Aviation is, like all engineering pursuits, full of tradeoffs. You can fly farther but carry less payload and travel slower, or you can fly faster but burn much more fuel and lose some range. You can go supersonic with small, thin, wings, but then you can’t slow down for landing below 170kts. You can land at 45kts, but then you will cruise at only 110kts.

It’s much the same with the payload/spray rate/coverage relationship for spray aircraft. If you are spraying at ULV rates of .5gpa, you can cover 10 times more area than you can when spraying at 5gpa, but put less product on each acre you treat.

The first aircraft we are designing, the Edison Heavy1, will include a 150gal hopper as the base option and will have enough fuel (battery capacity) to stay up in the air for about an hour and a half. How much flight time do we really need with a 150gal hopper, though? Here we actually answer this question by calculating the time to empty the hopper at different spray rates, speeds, and hopper sizes. (Note: these are purely spraying flight times, not including maneuvering, lane changes, and takeoffs/landings.)

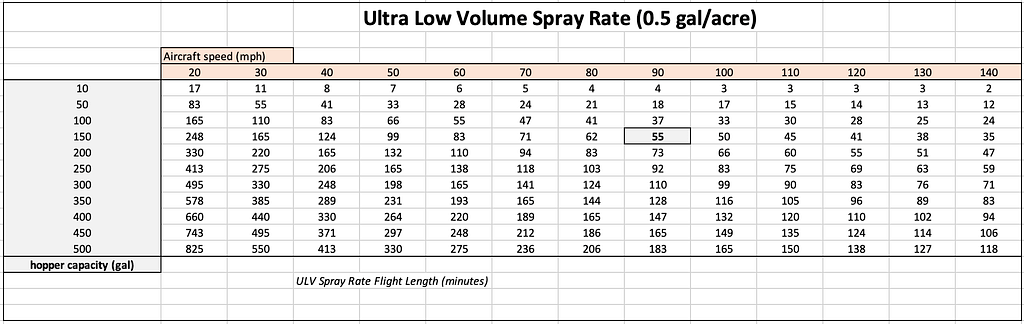

Table 1: ULV (.5gpa, 5 L/ha) speed vs coverage

What this tells us is that when flying at 90mph and carrying 150gal of product, spraying at .5gpa, our total spray time to an empty hopper is 55 minutes. With a 1.5hr max endurance, this is acceptable, as we have to reserve more time for takeoff, landing, and lane changes. What happens when the spray rate goes up?

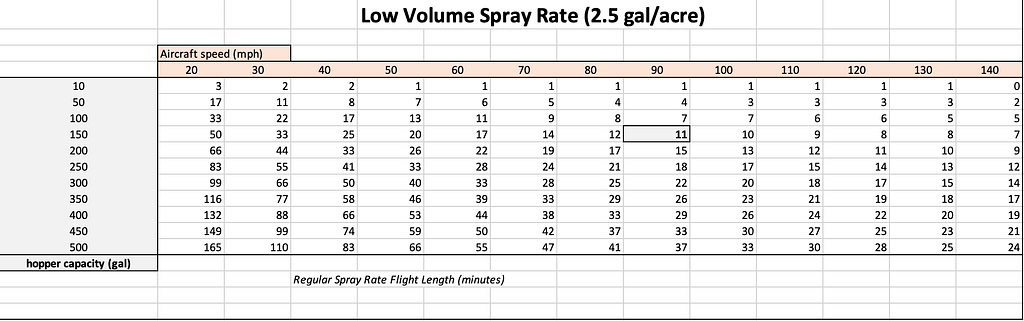

Table 2: LV (2.5gpa, 25 L/ha) speed vs coverage

This is very straightforward – spraying 5 times faster cuts the time to empty by a factor of 5. We can only fly for 11 minutes (spray time only) until the hopper is empty. Why carry enough batteries to fly for 1.5 hrs if you’ll be refilling in a little over 11 minutes? Great question! Here is our final scenario with a higher spray rate of 5gpa.

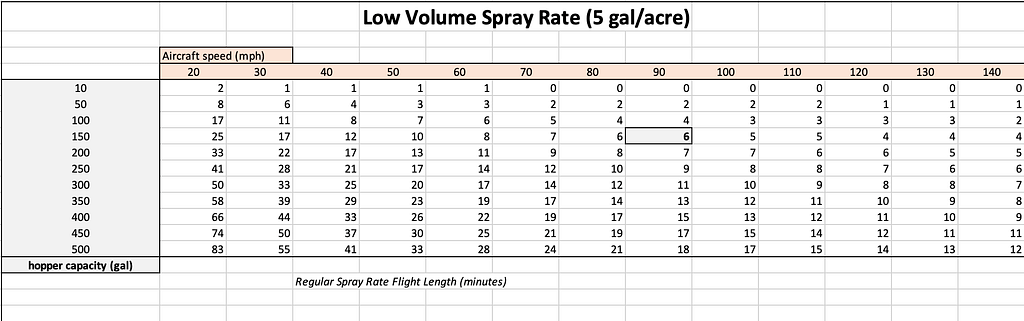

Table 3: LV (5gpa, 50 L/ha) speed vs coverage

- ULV 0.5gpa: 300 acres

- LV 2.5gpa: 60 acres

- LV 5gpa: 30 acres

Except for the ULV scenario, we are carrying too much battery or too little hopper size. What is the optimal solution? If you are spraying at 2-3gpa most of the time, then going from a 150gal hopper to 200gal means carrying 400lbs extra weight. Where can we make a compromise?

The easiest way to do this is to carry half the batteries. A full pack designed for 1.5hrs of flight time weighs about 900lbs. Half of this pack is 450lbs. Going from a 90min endurance to 45min is a small tradeoff when our 2.5gpa spray time with 200gal of product on-board is 15 minutes. By doing this we are also increasing our total field coverage from 60 acres per flight to 80 acres.

Can we compromise further? Well, yes, but then you have diminishing returns. by cutting the battery in half again, you save 200lbs, which is only 25gal. That is another 10 acres covered at 2.5gpa.

Our overall goal at Edison Aerospace is to design a modular system that can be adjusted for many different missions, and as we continue through our R&D process, this is one of the key goals that we are keeping in mind to bring you as good an aerial spray platform as we possibly can while making you more money through operating cost savings of 45% compared to most turbine aircraft.

If you are a spray operator, please contact Gene at gene@edison.aero or +1-310-210-2026 to get on the list of free evaluation demos we’ll be scheduling once our full-size prototype is ready for the world.

Thank you!